Pune / Buers (AT): Urban train operations generate vibrations and noise, which affect the people living and working in its surroundings.

The mass-spring system from Getzner efficiently mitigates such vibrations and the secondary air-borne noise. Getzner’s mass-spring system is installed in over forty cities worldwide – amongst them are the Indian cities of Bangalore, Delhi, Lucknow and Mumbai.

The train operations generate vibration energy at the track superstructure because of high dynamic loads. This vibration energy propagates through the ground and once it reaches a building, depending on the dynamic characteristics of the building, it can be perceived as vibrations or can be heard as secondary air-borne noise, adversely impacting the lives of people in the vicinity of the metro corridor.

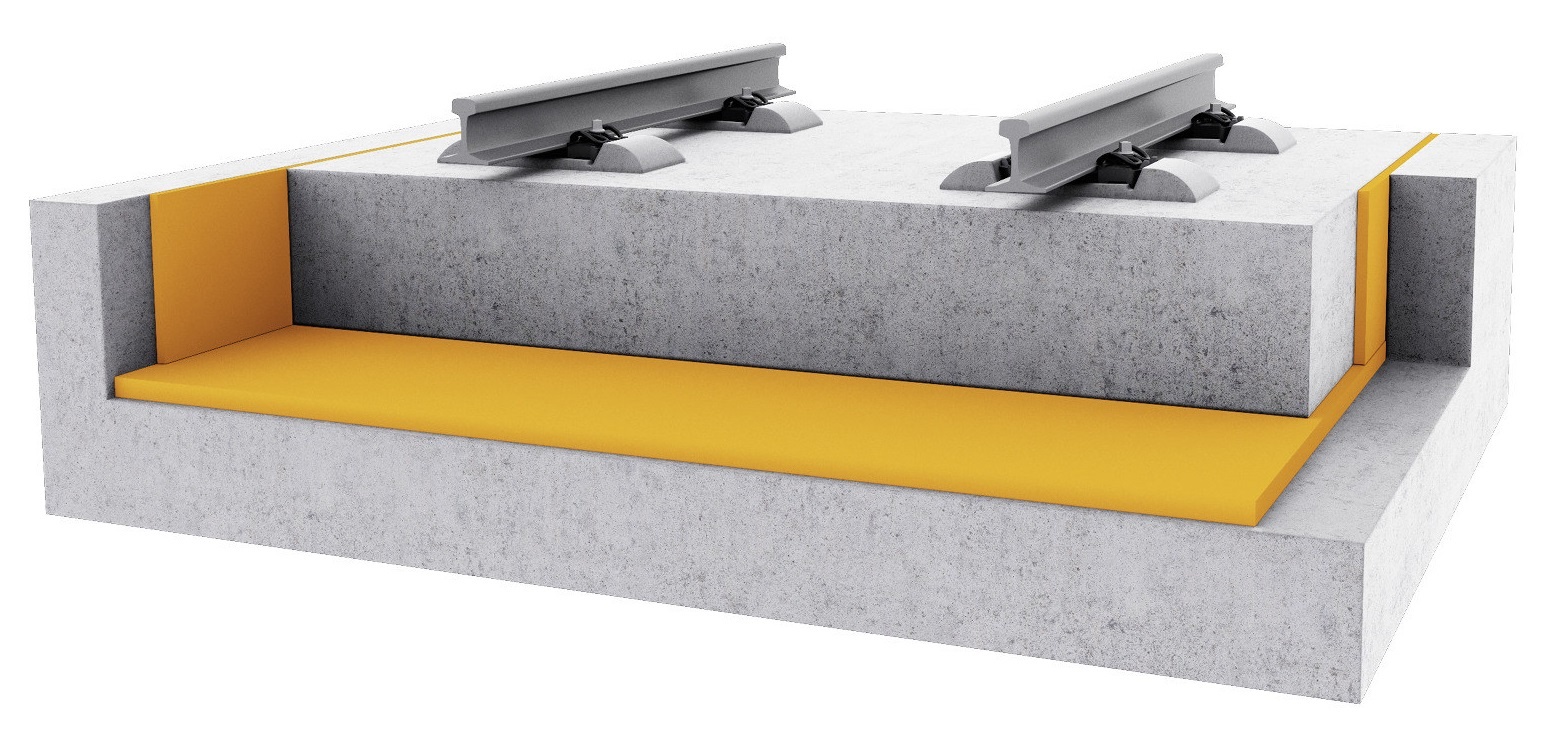

“The effect of vibration and noise is different in every building depending on it structural characteristics. That is why we aim to control the vibrations at the source itself – the metro railway track”, explains Sanjay Risbood, CEO and Resident Director of Getzner India. “The goal of mass-spring systems is to elastically decouple the track superstructure from its surrounding in order to reduce the transmission of vibrations.”

The Austrian company Getzner is the world technology leader in the field of vibration isolation in the railway, construction and industry sectors.

The mass-spring system from Getzner uses the high quality micro-cellular polyurethane materials Sylomer® and Sylodyn®. Risbood: “These high-quality PU materials guarantee the long-term performance of the mass-spring system. This is of utmost importance because the maintenance or replacement of a mass-spring system after the installation and the start of train operations is very expensive, time consuming and sometimes not feasible, too. Hence, the mass-spring system should necessarily perform throughout the life of the track”.

Until today, Getzner has supplied more than 450 mass-spring systems worldwide. They all are performing effectively from the last 40 years without a need of maintenance or replacement.

Full surface mass-spring systems in India

Depending on the economic and technical requirements of the customers, Getzner offers three types of mass-spring systems: Full surface, strip bearing and point (discrete) bearing. Sanjay Risbood: “We have supplied full surface mass-spring systems for projects in cities of India like Delhi, Bangalore, Lucknow and Mumbai. The full surface mass-spring system is the most cost effective, it is easy to construct and gives the desired long-term performance.” With a full surface mass-spring system, the natural frequency in the range of 14 to 25 Hz can be achieved.

Mr. Risbood explains: “Getzner has already supplied several point and strip type mass-spring system solutions to various urban, mainline and high-speed train systems worldwide, wherever there is a need for lower natural frequency.”

Getzner Werkstoffe GmbH – the good vibrations company:

Getzner Werkstoffe is the leading specialist in the field of vibration isolation and protection. The company was founded in 1969 as a subsidiary of Getzner, Mutter & Cie. Its solutions are based on the products Sylomer®, Sylodyn®, Sylodamp® and Isotop®, all of which were developed and manufactured at Getzner’s own facility. They are used in the rail, construction and industry sectors to reduce vibrations and noise, improve the service life of bedded components and minimise the need for maintenance and repairs on tracks, vehicles, structures and machines.

Getzner markets its vibration protection solutions around the world. Alongside its locations in Buers and in Germany, Getzner also has offices in China, France, India, Japan, Jordan and the USA. Its tightly-knit distribution network in Europe is complemented by its distribution partners in the USA, South America and the Far East. Partners in a total of 35 countries around the world distribute Getzner Werkstoffe products to every location. By reducing noise and vibrations, Getzner is making a valuable contribution towards enhancing the quality of living and working conditions